Hammelmann then and now

Founded in 1949 by Paul Hammelmann in Oelde, Westphalia, the company decided to start manufacturing high-pressure pumps and cleaning systems in 1955, thus laying the foundations of the current business. Hammelmann became a pioneer in the field of hydrodynamics and was responsible for many trailblazing innovations.

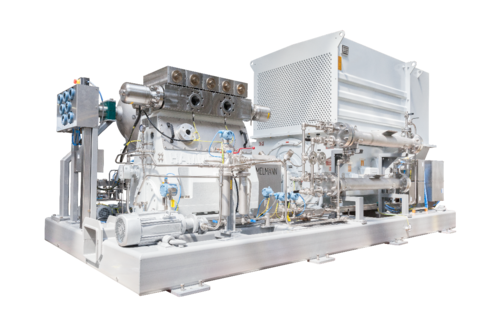

In endeavoring to solve individual problems and improve existing solutions, the company has grown from modest beginnings into an internationally recognized manufacturer of high-pressure technology products. The plant in Oelde boasts state-of-the-art machinery and covers an area of 30,000 square meters.

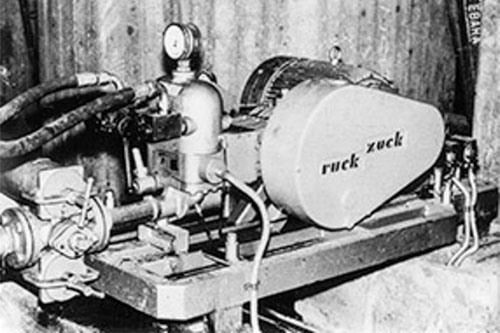

The DP 60 was the first pump produced in Oelde. It had an operating pressure of 60 bar and a flow rate of 60 l/min and was used for cleaning applications in the paper industry. Today, we can achieve operating pressures of over 4000 bar and flow rates up to 3000 l/min with Hammelmann high-pressure pumps.

Decades ago, the point of fitting a cover over a high-pressure unit was just that. Today, the covers have more to do in controlling sound and exhaust emissions. Hammelmann also supplies individual elements such as dust particle filters and electronic microprocessors and controllers.

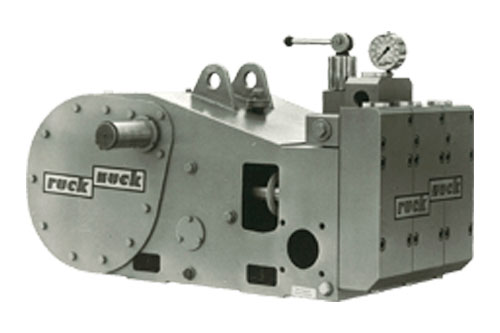

During the mid-1960s, operating pressures only reached 500 bar. In 1974, Hammelmann revolutionized high-pressure technology with the introduction of the friction-free plunger seal assembly. This metal-to-metal sealing system enabled operating pressures of up to 2000 bar to be reached for the first time together with a high service life.

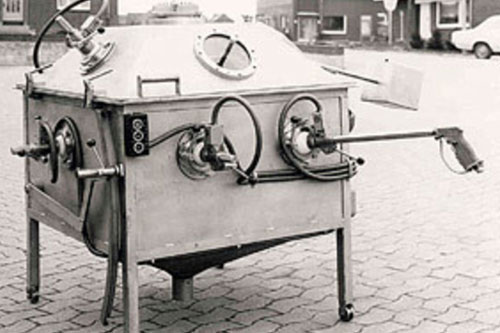

In 1969, Hammelmann launched the Dockmaster as the first semi-automatic ship cleaning machine. Today’s version of the unit is environmentally friendly and features direct suction, and is not only used in shipyards but also for the selective removal of concrete in road construction.

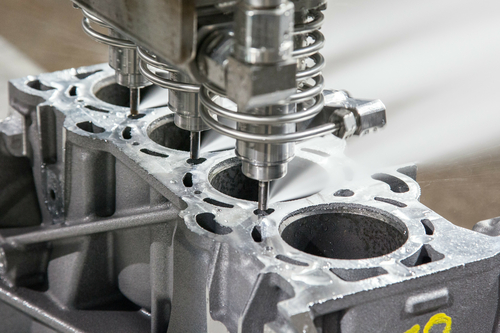

Nowadays, water tools are used more and more in automatic cleaning processes. Cleaning cast parts is just one of many examples. Whereas these previously could only be cleaned by hand (if at all), robots now carry out the work with the help of high-pressure technology made by Hammelmann.

.